Zetwerk is with you every step of the way

Precision Die Cast Parts Manufacturer With Excellence in Quality, Service, and Best Pricing

Submit Specs

Submit your specs and our engineers will review your die cast project details.

Approval

Once approved, we will move forward and send out die cast part samples for approval.

Wholesale Pricing

Our global manufacturing capabilities ensures competitive pricing.

We Deliver Too

Your parts in a warehouse ensures production lead times are less than 5 days.

Custom Die Casting Capabilties

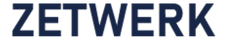

Zetwerk streamlines the industry as your top supplier for premium manufactured die casting parts and services in North America. Accelerate your time to market, boost product sales, cut project expenses, and strengthen your supply chain with Zetwerk in 2023.

The Die Casting Process: A Journey into Efficient Metal Fabrication

Request a Quote

Skilled and Experienced Die Casting Company

Our team of engineers, technicians, and skilled workers is the backbone of our success. With extensive experience in the die casting industry, they possess the expertise to deliver products that meet your exact specifications. From design to manufacturing and quality control, our professionals work tirelessly to ensure every die cast part and product that leaves our facility is of the highest standard.

Our team of engineers, technicians, and skilled workers is the backbone of our die casting companies success.

At Zetwerk, we understand the significance of advanced technology in producing top-notch die casting products. Our state-of-the-art infrastructure is equipped with the latest die cast machinery and tools, ensuring superior product quality and quick turnaround times. With our technology-driven approach, you can rest assured that your die cast project will be handled with the utmost precision and efficiency.

Managed Inventory

Quality Control

Supply Chain

Tooling Design

Die Casting Services

Our Expertise

Zetwerk offers comprehensive die casting services using a variety of metal alloys including aluminum, brass, bronze, copper, magnesium, and zinc. Our high-pressure die casting machines range from 180 to 2500 tons, with the capability to produce low-pressure die cast parts weighing up to 30 kg. Our production tools offer high-volume multi-cavity production (100-500K shots) and perpetual tooling with a lifetime guarantee. We provide additional services such as secondary CNC machining, a range of surface treatments, and straightening. Our facility is certified with AS9100D, ISO 14001:2015, ISO 45001:2018, ISO 9001:2015, IATF 16949:2016, and ISO 13485:2016.

Transportation

*Some common die-cast parts used in the transportation industry include: engine blocks and transmission components, housings, gears, die-cast wheels for motorcycles, brackets, mounts, and structural components like chasis and frame support to ensure strength and durability.

Construction and Infrastructure

*Some common die-cast parts utilized in the infrastructure and construction sector include: handles, locks, hinges for components in doors and windows, lamp housings and brackets for outdoor municipal lighting fixtures, faucet handles and spouts for plumbing, electrical boxes and enclosures, as well as structural components such as brackets, connectors, and supports for buildings and infrastructure projects.

Consumer Products

*Some common die-cast parts used in the consumer products sector include: manufacturing of casings and enclosures for smartphones, laptops, and electronic devices; kitchen appliances like blenders, toasters, and coffee machines; power tool components like drill bodies, saw guards, and gear housings.

Industrial Machinery and Equipment

*Some common die-cast parts used in the industrial machinery and equipment industry include: gearboxes and housings, pumps and compressors, such as impellers, casings, and valve bodies; construction of machine tool components, including bases, frames, and structural elements, the manufacturing of electric motor housings and generator components.

Aerospace and Defense

*Some common die-cast parts used in the aerospace and defense industry include: components of aircraft engines, manufacturing of structural elements for aircraft airframes (wing ribs and fuselage frames), and landing gear components like brackets and fittings, as well as satellite components such as antenna brackets and fixtures.

Energy and Utilities

*Some common die-cast parts used in the energy and utilities sector include: electrical connectors, terminal blocks for power transmission systems, certain parts of electrical transformers, the manufacturing of components for power generation equipment, including turbine casings and generator components; parts for renewable energy systems, such as wind turbine parts and solar panel extrusions.

Reduce Die Casting Costs With Zetwerk

Submit Project Information

Get a Die Casting Quote Today